Fully automatic can opener CEM

High performance for sophisticated workflows

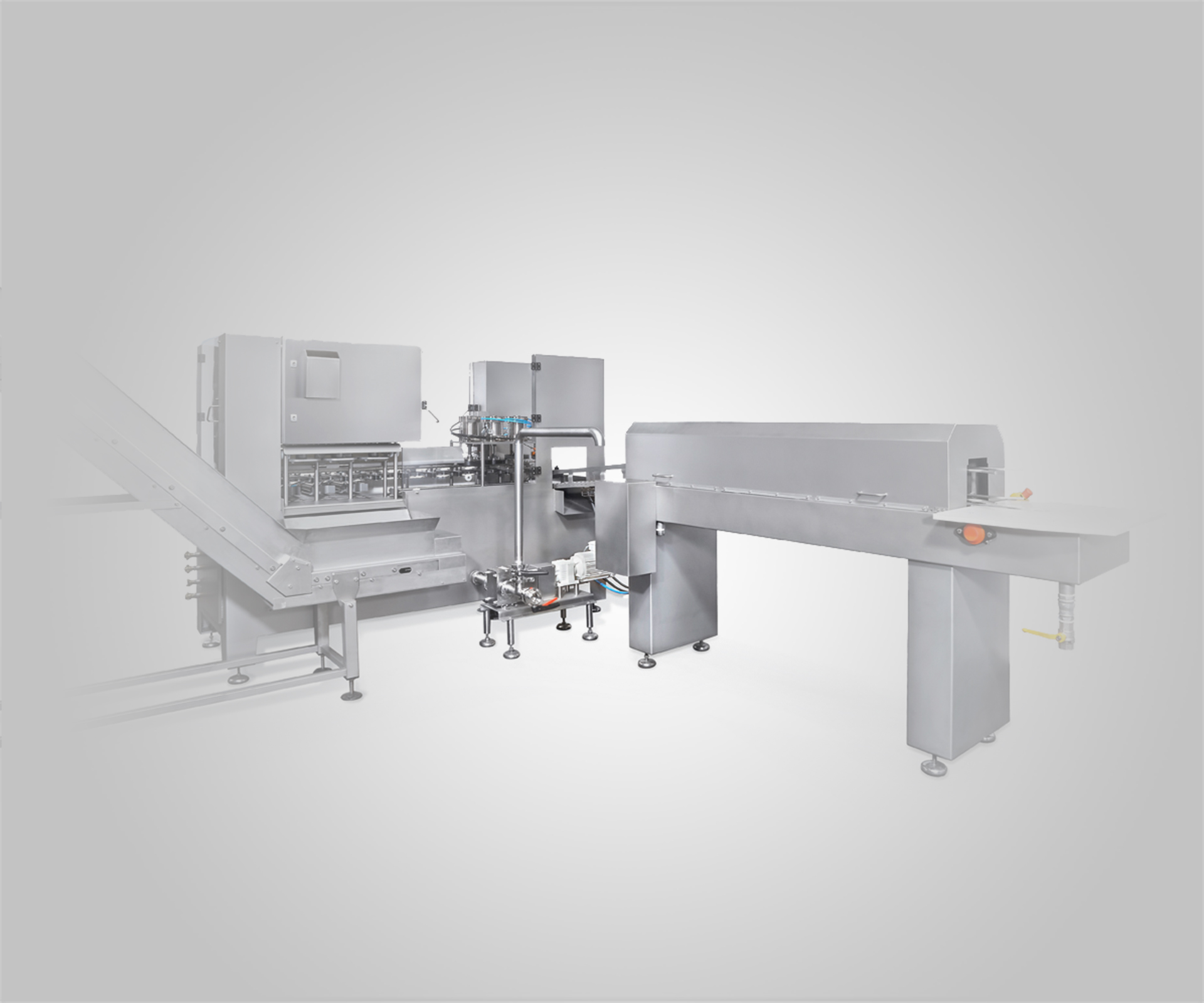

Our fully automatic can openers in the CEM series open, empty, clean and crush cylindrical cans. With up to 2200 cans per hour, these industrial can openers are suitable for integration into processes in the food industry. The fully automatic series hygienically processes different can formats without retooling the machine.

Technical data of the CEM series

| TYPE | CEM 2.0 | CEM-1200 | CEM-2200 |

| Output cans / h | 900 | 1200 | 2200 |

| Products | all | liquid / low viscosity | liquid / low viscosity |

| Can sizes kg | 2+3+5 / 10+12 | 2+3+5 | 2+3+5 |

Our various models of fully automatic can opening machines including the new CEM 2.0 are characterized by their space-saving design. The entire machine, punching knives and punching heads are made of stainless steel.

The machines in the CEM series are extremely versatile and can easily open cylindrical cans that meet industrial standards of 2 kg, 3 kg and 5 kg, with can diameters ranging from 153 mm to 157 mm. They also process cans weighing 10 kg and 12 kg with can diameters between 230 mm and 233 mm. Regardless of the weight of the cans, can heights from 115 mm to 310 mm can be opened without time-consuming format changes, which reduces set-up times to a minimum.

Thanks to the can rinsing device they achieve an impressive emptying rate of up to 98%, which increases productivity and minimizes waste. The integrated can crushing device is another feature worth mentioning. This technology reduces the volume of waste by up to 80 %. This not only minimizes the space required for disposal, but also reduces the environmental impact by reducing the frequency of waste disposal.

Advantages of fully automatic can opening machines

With our fully automatic can opening machines you benefit from numerous advantages:

- Our machines are characterized by low energy consumption.

- The CEM model is low-maintenance, which makes your investment even more attractive in the long term.

- Our machines are designed so that you can get by with a minimum of operating personnel.

Our can opening machines of the CEM series are extremely versatile and adapt to the most diverse requirements in the food and beverage industries. They are suitable for both continuous and batch operation. Operation is simple and the possibility of quick cleaning ensures a smooth production process and any product changeover in your factory.

Views of our CEM machines

Features

Downloads

Presentation CEM-600, COM, HDO

Presentation CEM-1200 and CEM-2200

Brochure CEM-600

Interested? Please ask your questions or request a quote.

Functioning of the CEM-1200 and CEM-2200

The CEM-1200 and CEM-2200 can openers are specially designed to meet the needs of the beverage industry. These machines are high-performance machines that open cans with a capacity of 3 kg and empty the contents. Cans with liquid and pasty contents such as mango concentrate are processed without any problems. The CEM-1200 is capable of processing 1200 cans per hour while the CEM-2200 is even more powerful and can process 2200 cans per hour.

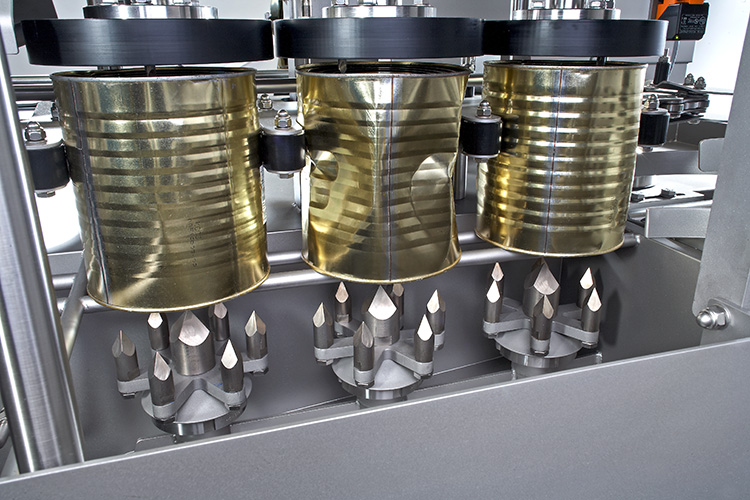

The full cans are fed into the machine via an infeed roller conveyor. The cans are opened using special pricks that penetrate the bottom from below. Most of the contents flow out of the can through the openings. The cans are then transported to the rinsing station. There they are rinsed with a mixture of sterile compressed air and water. To keep the volume of waste as low as possible the cans are then forwarded to the can crushing device. There they are automatically crushed and then transported down a chute into a container for disposal. The product is collected in a collection container and transported further by a pump.

Functioning of the CEM 2.0

The CEM 2.0 is a fully automatic can opening machine used in the food industry. It is mainly used in companies that produce ready meals, pizzas, delicatessen salads or fruit preparations. The CEM 2.0 is capable of processing up to 900 cans per hour. In addition to cans with liquid or paste-like contents such as tomato concentrate, it also processes cans with chunky contents such as olives or pineapple.

Like the CEM-1200 and CEM-2200 models, the CEM 2.0 performs the steps of opening, emptying, rinsing and crushing the cans. In standard operation, the machine is loaded with cans manually.

The opening and emptying process of the CEM 2.0 differs from that of the CEM-1200 and CEM-2200. With the CEM 2.0 the full cans are transported to the opening station where a punching knife punches out the lid and holds it in place. The can lids are ejected before the next can is opened and transported out of the machine via the can ejection chute. The opened can is then transported to the emptying station. Here, the can is tilted by 180°, which enables to empty it and collect its contents in a container. The emptied cans are passed on with the opening facing downwards and rinsed. The rinsed cans are crushed and conveyed into the same ejection chute.

Modular machine extension

We offer you comprehensive solutions for expanding your CEM machine. Our versatile extensions optimize your production processes and increase the performance of your system. Our range of extensions includes the integration of a can washing system directly upstream of your CEM machine. This system cleans, disinfects and blows off the cans. We also offer solutions for the smooth feeding of full cans into the CEM machine, the removal of the crushed cans and the lids and the gentle transfer of the products via conveyor belts or pumps.

We provide you with expert advice, help you with the planning, take care of the engineering, shipping, customs clearance, installation and commissioning and also carry out the CE certification of your entire KA-Process system.

Service

Maintenance and inspection

Even though our machines are low-maintenance machines, regular inspection is the key to ensuring the availability and extending the service life of can opening machines. Our technicians carry out inspections and maintenance in order to detect and rectify any faults at an early stage.

Repairs and spare parts

If your machine needs to be repaired, we are there for you. We have an extensive range of original wear and spare parts, which ensures that your can openers are ready for use again in the shortest possible time.

Training and support

Our CEM series can openers are easy to operate by trained personnel. During commissioning, our experts provide the operating personnel with the knowledge and skills they need to operate the machines safely. In addition, our support team is available to answer your questions and concerns.

FAQ about the fully automatic can opener CEM

Other can openers

Manual can opener HDO

Opening and crushing via 2-hand control, manual emptying.

Entire machine made of stainless steel

Entire machine made of stainless steel